an Open Source Ventilator Project

Breath4Life is a voluntary, non-profit, and open-source effort by a distributed team of engineers, doctors,

industry players, investors, to design and produce low cost medical ventilators.

[ Based in Belgium, and focused on helping at country-level first ]

Story

The Covid-19 crisis puts hospital systems -especially Intensive Care Units- under intense pressure.

The current Covid-19 crisis puts healthcare systems and resources under intense pressure. Medical ventilators are a key component of intensive care beds, but at risk of being in limited supply, if and when the current coronavirus pandemic amplifies. Many countries have started industrial efforts to produce low cost ventilators.

Breath4Life is a voluntary, non-profit, and open-source effort originated at UCLouvain university, by a distributed team of engineers, doctors, industry players, investors and other disciplines, to design and produce low cost medical ventilators.

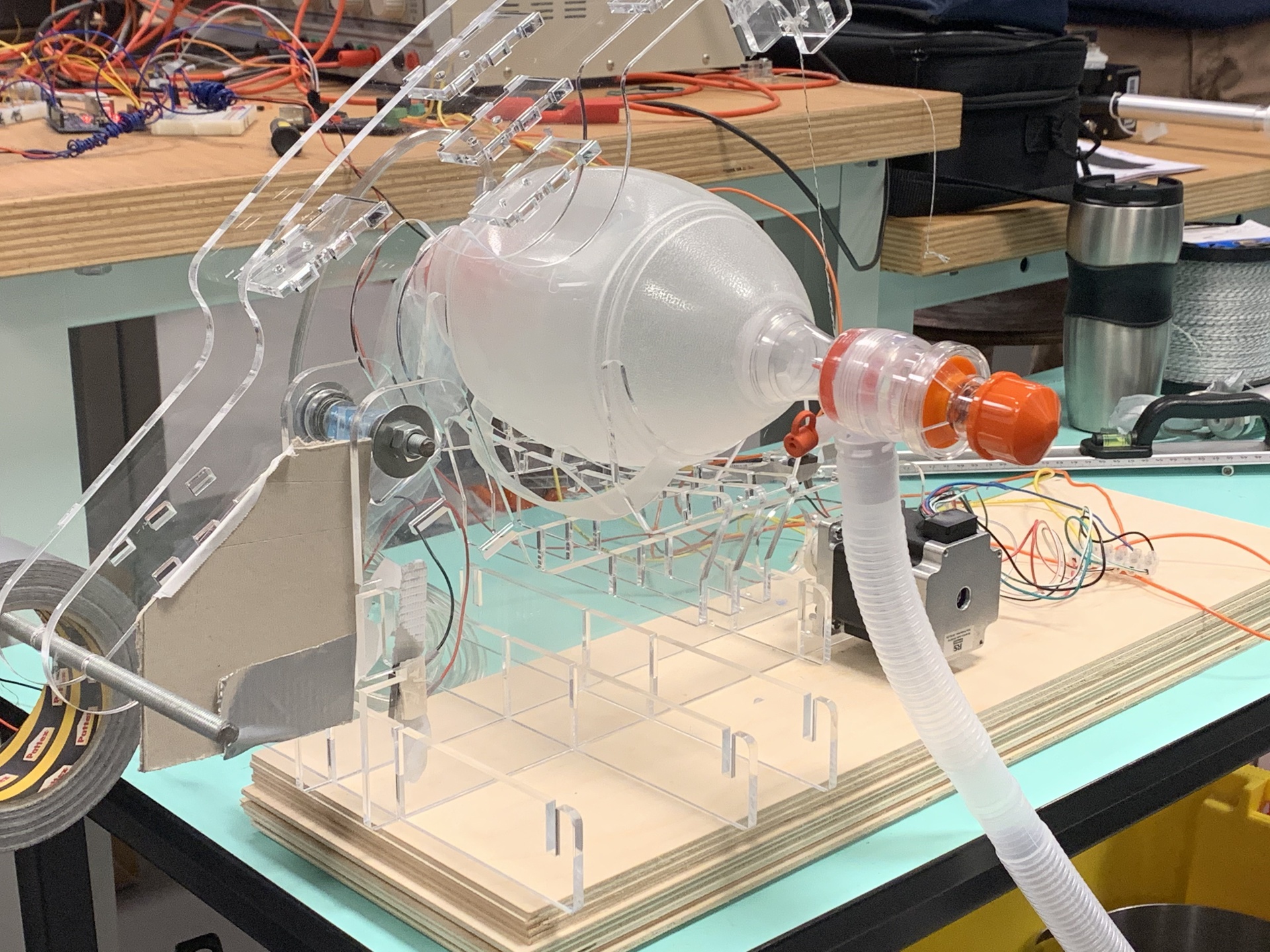

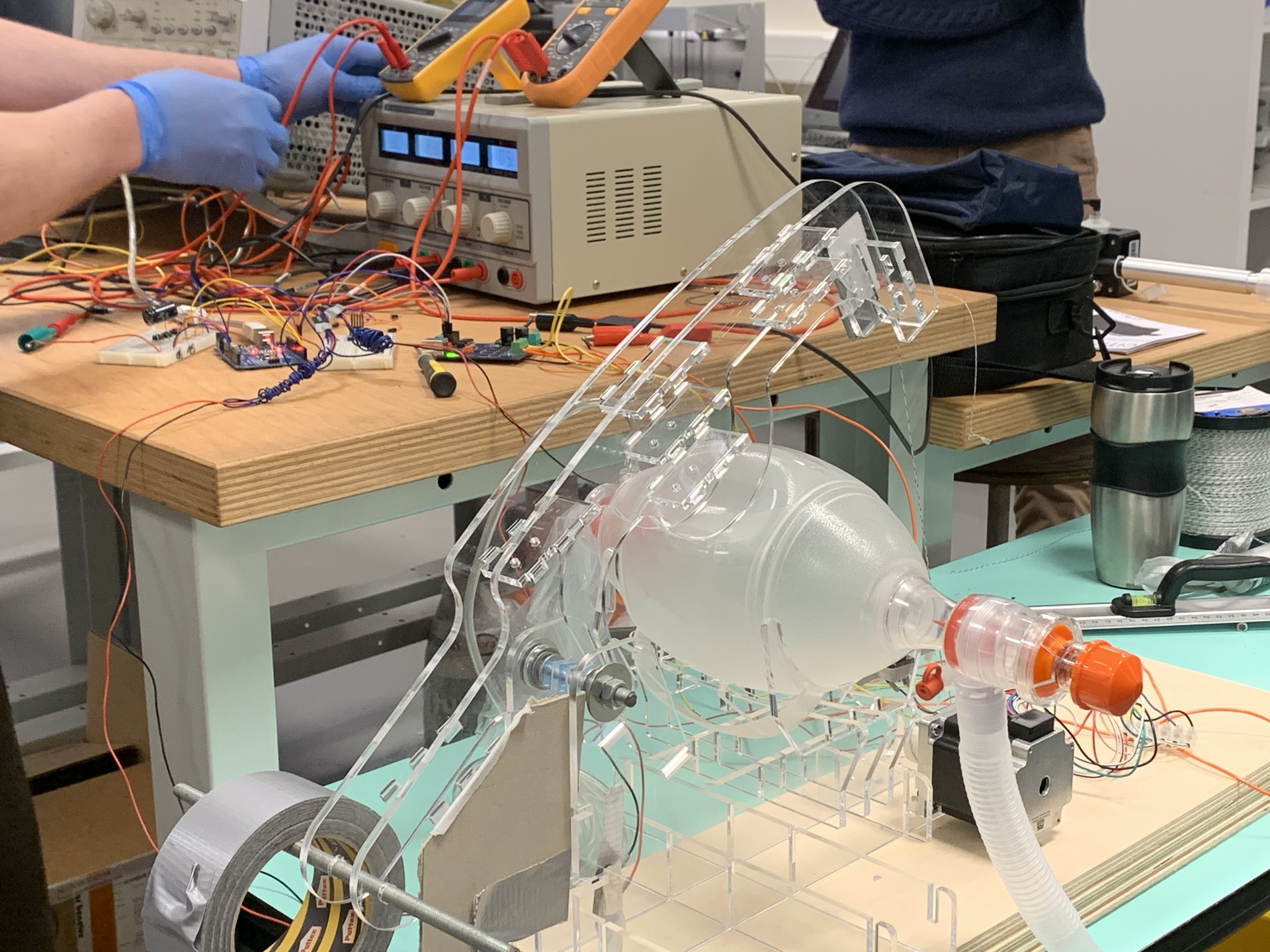

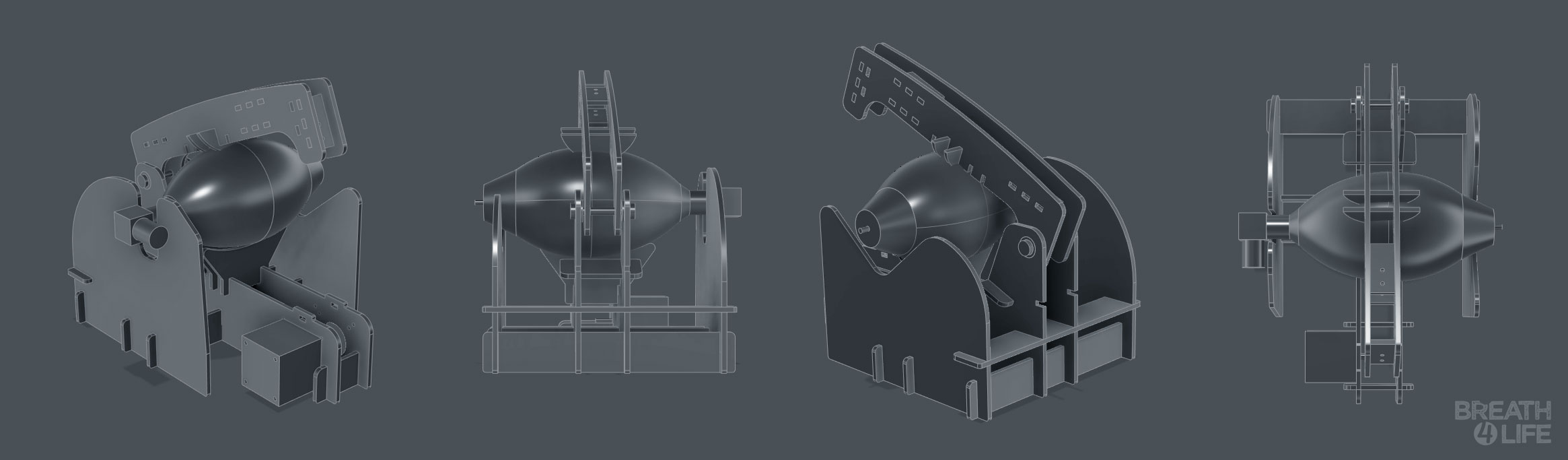

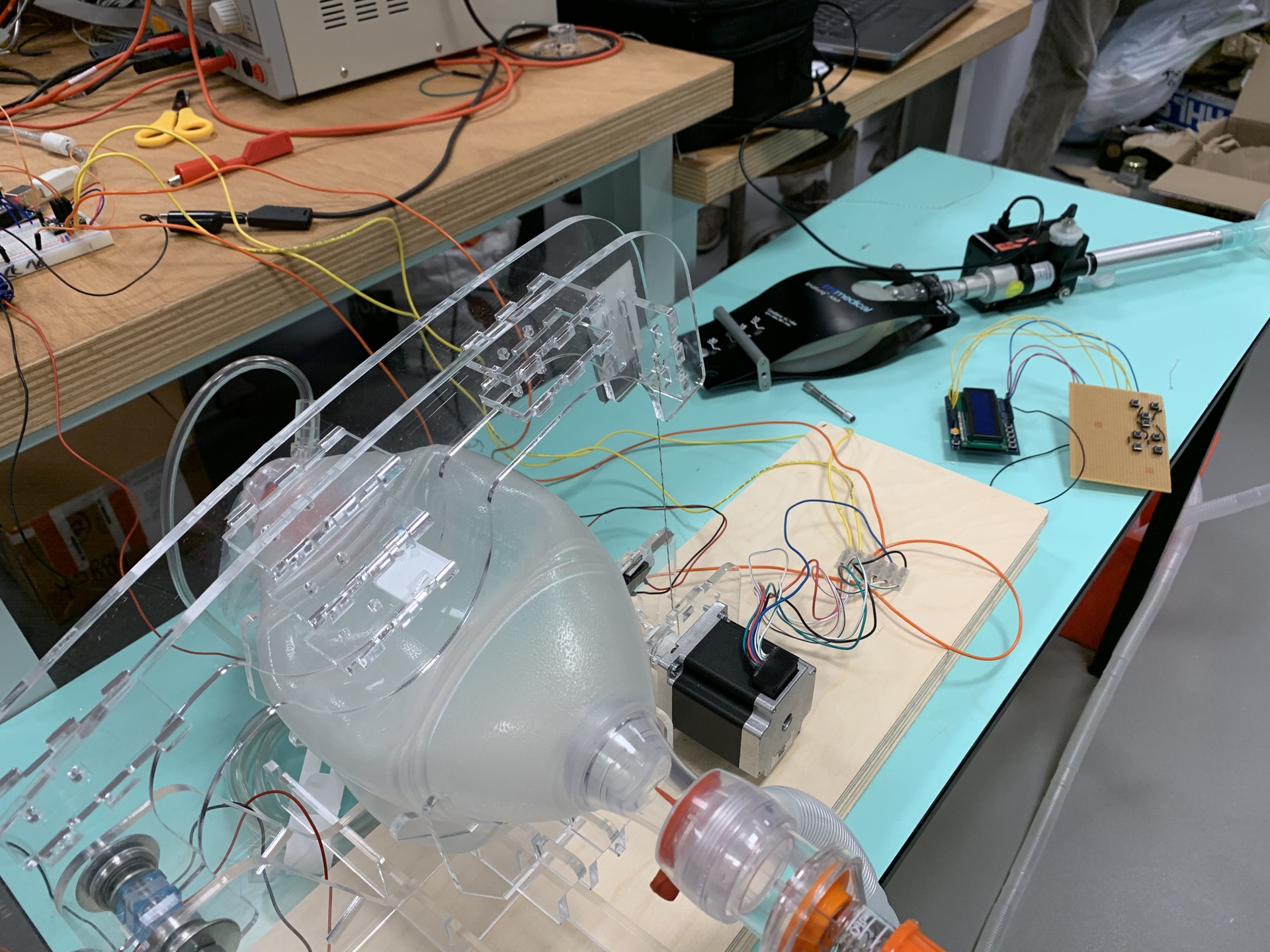

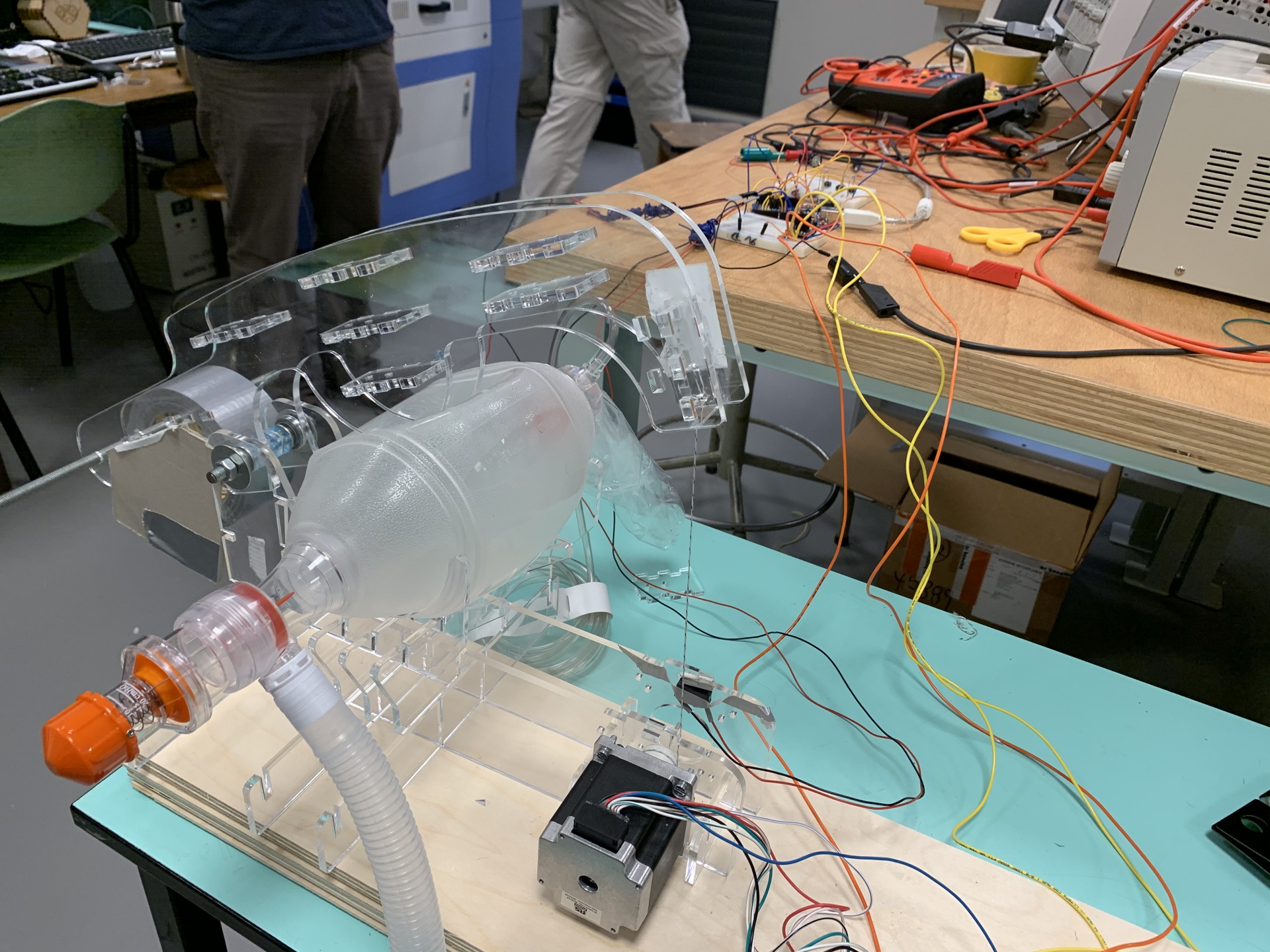

As of early April, we are working on the first prototypes, preparing to go though a test suite, to ensure an adequate level of adherence to quality and medical standards, to conform to some “fast track” regulatory requirements that governments worldwide are starting to make public.

Also, in case mass production is needed, an industrial effort is being coordinated, mostly with the aerospace industry of Wallonia (Sonaca, Safran Aeroboosters, etc.)

=> full story

Breath4Life in the Press (in French)

Current Status

April 2nd, 2020

First prototypes produced. Tested on artificial lung.

Planned test on (healthy) patient.

Disclaimers

No certification.

Not available for purchase.

If you want to help designing or building it, get in touch with us

There are already plenty of people working on the project now (300+)

If you can bring some design or production help, get in touch with us.

OpenHub (UCLouvain) is managing the R&D / design part.

Coexpair is coordinating the effort to industrialise the production.

Please read our FAQ, and contact us through our Contact form

If you want to support us financially,

The Fondation Louvain has setup a page to support us financially (tax deductible in Belgium)

FAQ

Q : Why is this effort needed ?

A : In an ideal world, this would not be needed. However, the spread and speed of the Covid-19 pandemia puts hospital systems under intense stress. One of the most need items are breathing ventilators. In many countries, engineers and industrialists are racing to provide inexpensive, quickly built, alternative solutions.

Note that this is an effort for Belgium ; there are many similar efforts underway in other countries.

Q : Is this ventilator currently available ?

A : (short answer) currently (April 2nd), NO.

Only a handful of prototypes exist, that are currently undergoing testing (medical, durability, security,...)

Q : Is this a "geek" "solution" ?

A : It is designed by a large distributed team of experienced engineers. Mostly, it is designed with constant contact with doctors, to ensure that it is in line with medical requirements, and clinical practice.

Q : What is the quality level of this solution ?

A : Compared to commercially available fully certified equipment, this is not at the same level. However : it is designed with a rigorous process, including the main requirements from existing standards for medical devices and respirators in particular, and in line with the best practices of the medical and aeronautical industries. A full certification being totally out of the picture (standard timing is between 12 and 24 months!), the team is working with the authorities (AFMPS/FAGG) to get a fast-track authorization process, with sufficient evidences of the risk management (not to create additional risks) but pragmatically letting the projects go forward as fast as possible.And in a state of emergency, and potentially lack of commercial equipment, it could save lives.

Q : When will it be available ?

A : It is quite hard to predict, dependant on clinical, regulatory, supply chain conditions. However : small scale production (a dozen) could happen by week 16 (April 13th), a few dozens by week 17 (April 20th), and in hundred(s) by week 18 (April 27th). Note that this is very dependant on many factors outside our scope, such as supply chain management, and assembly conditions made much more complex because of Covid-19 related safety measures.

More coming soon.

Who ?